That old, stiff gate valve in your basement isn’t a charming relic; it’s an engineered failure waiting to happen, and relying on it is an act of plumbing negligence.

- Ball valves guarantee a reliable, leak-proof shutoff even after a decade of inactivity, unlike gate valves which are notorious for seizing or breaking.

- A “full port” ball valve is non-negotiable for your main line to prevent significant water pressure loss throughout your home.

Recommendation: Proactively replace your main water shutoff with a quality full-port ball valve *before* it fails during an emergency. It’s the best plumbing insurance you can buy for your property.

Imagine this: It’s 3 AM in the middle of a January cold snap in Montreal. You hear the unmistakable sound of spraying water from the basement. A copper pipe has burst. You rush downstairs, wading through rapidly rising water, and grab the round, red handle of your main water shutoff. You turn. It doesn’t budge. You grab a wrench for leverage, give it one desperate heave, and the stem snaps off in your hand. The water keeps gushing. This isn’t a bad dream; it’s the predictable outcome of trusting an obsolete piece of technology called a gate valve.

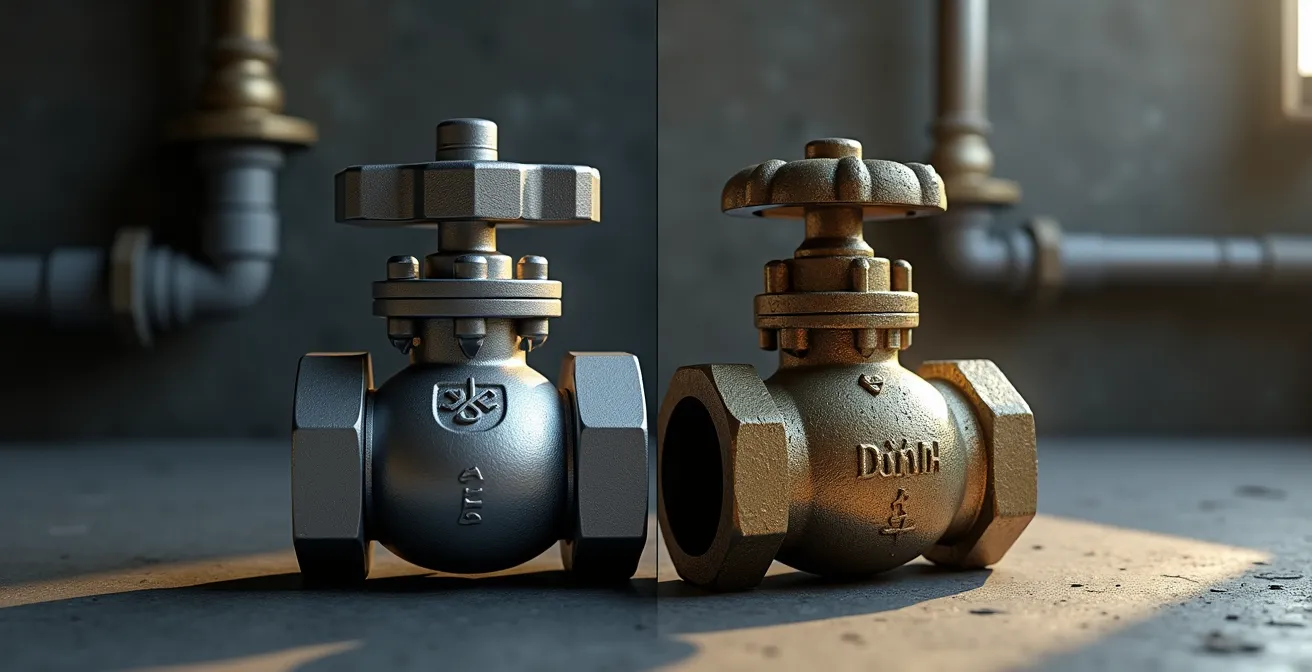

For decades, homeowners have been told that a valve is just a valve. As long as it’s there, it’s fine. But this is a dangerously simplistic view. In the world of modern plumbing, there are two main contenders for your home’s main shutoff: the old-school, multi-turn gate valve, and the modern, quarter-turn ball valve. Many assume the choice is a matter of preference, but it’s not. It’s a matter of reliability, performance, and frankly, common sense.

But what if the real problem isn’t just that gate valves are old, but that their very design is a blueprint for failure? The true key to securing your home isn’t just having a shutoff; it’s having one that is guaranteed to work flawlessly the one time you desperately need it, ten years from now. This is where the quarter-turn ball valve isn’t just a better option; it becomes the only responsible choice for a homeowner who values their property.

This guide will dismantle the outdated arguments and demonstrate, point by point, why installing anything less than a high-quality ball valve as your main shutoff is a calculated risk. We’ll explore the critical differences in design, the impact on your daily water pressure, the right materials for Quebec’s aggressive water, and how to operate these modern valves safely to protect your entire plumbing system.

This article breaks down the essential considerations for choosing and maintaining the most critical valve in your home. Follow along to understand the clear-cut case for modern plumbing technology and how it acts as the ultimate insurance policy for your property.

Summary: Upgrading Your Main Water Shutoff: The Definitive Guide

- Ball valve vs. gate valve: which will still close after 10 years of inactivity?

- Full Port: why is it crucial for not reducing your water pressure?

- Stainless steel or chrome-plated brass ball: which to choose for aggressive water?

- Valve with drain (Stop & Waste): essential for outdoor faucets

- Water hammer on closure: how to close a ball valve without breaking the piping?

- Where is the main water inlet hiding in a 1950s house?

- How to shut off water to a single faucet without turning off the whole house?

- Why Does an Emergency Plumber Cost 3x More Than Scheduled Maintenance?

Ball valve vs. gate valve: which will still close after 10 years of inactivity?

The single most important question for a main shutoff valve is not “does it work today?” but “will it work in a decade after not being touched?” This is where the fundamental design difference between a ball valve and a gate valve becomes a story of modern reliability versus engineered failure. A gate valve operates like a gate on a threaded rod; multiple turns are required to slowly lower a brass wedge to stop the flow. Over years of inactivity, especially with Quebec’s hard water, mineral deposits (scale) build up on these threads and the valve seat. The result is inevitable: the valve either seizes shut, or worse, seizes open and the stem snaps when you try to force it closed in an emergency.

A ball valve, in contrast, is elegantly simple. A lever rotates a solid, perforated ball 90 degrees. The internal surfaces are smooth, and the action is a swift, clean wipe across the seals. There are no exposed threads to corrode or complex mechanisms to jam. This design is inherently more resistant to scaling and seizing. When you turn the lever, the force is applied directly and powerfully, shearing away minor deposits. This means that after 5, 10, or even 15 years of sitting dormant, a quality ball valve has an exceptionally high chance of closing perfectly and providing a watertight seal. A gate valve, after the same period, is a gamble at best. For a component that serves as your home’s primary water safety device, “gambling” is not an acceptable strategy.

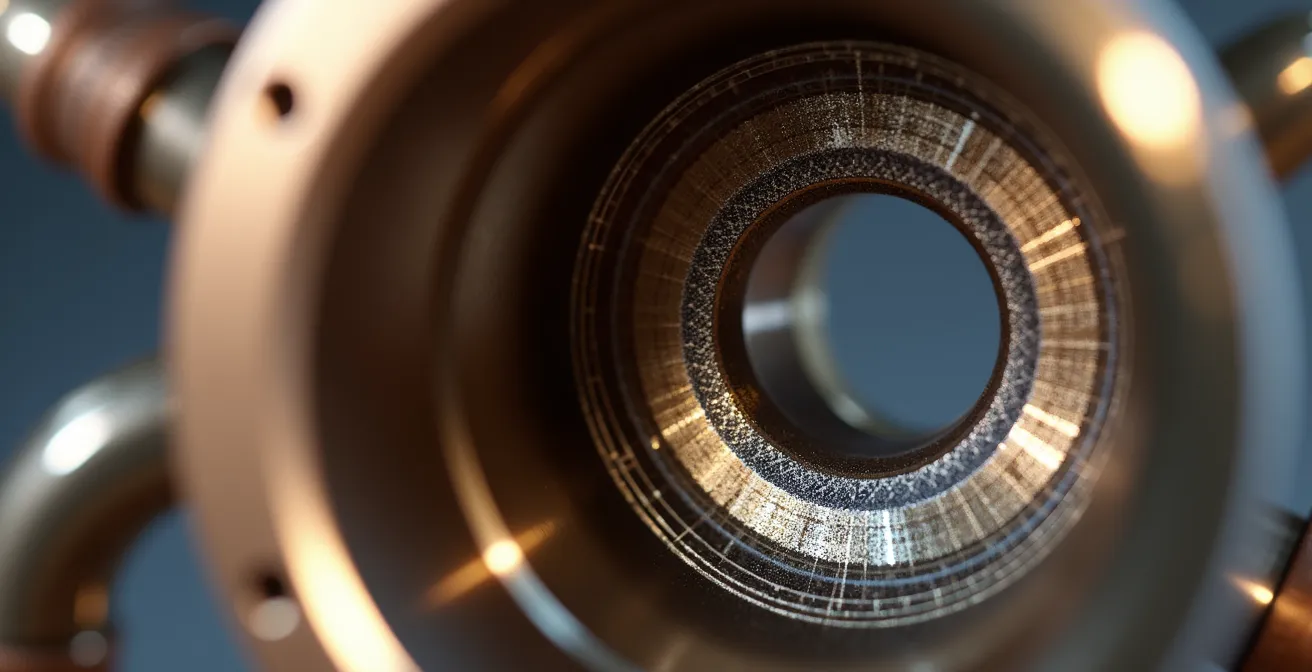

Full Port: why is it crucial for not reducing your water pressure?

When we talk about upgrading a main valve, the conversation often stops at the mechanism. But there’s a second, equally critical factor that directly impacts your daily life: the port size. The “port” is the hole through the valve that water flows through. An old gate valve or a cheap, standard-port ball valve has an opening that is noticeably smaller than the pipe’s diameter. This creates a permanent bottleneck at the very start of your home’s plumbing system, like squeezing a garden hose. The result is a permanent reduction in flow rate and a measurable drop in water pressure to every single fixture in your house. You might blame your city’s water supply, but your own valve could be the culprit.

This is why a “full port” ball valve is non-negotiable for a main water line. A full port valve is engineered so that the hole in the ball is the exact same diameter as the connecting pipe. When it’s open, it’s as if there’s no valve there at all—the flow is completely unrestricted. This ensures that you get the maximum pressure and volume your municipal connection can provide. The difference is not trivial; studies show that standard port valves can cause a 25-40% pressure loss compared to a full port design. If you’ve invested in a new shower system or have a multi-story home, strangling your water supply with a standard-port valve makes no sense.

The visual cross-section makes it clear: the water has a straight, unimpeded path. This design integrity is fundamental to a modern plumbing system’s performance. The minimal pressure drop associated with a full port valve is a key reason it is the superior choice for main lines.

This table illustrates the performance difference. For a main water line where maximum flow is essential, the choice is obvious.

| Valve Type | Flow Restriction | Pressure Drop | Best Application |

|---|---|---|---|

| Full Port Ball Valve | 0% (Same as pipe diameter) | Minimal | Main water lines, tankless heaters |

| Standard Port Ball Valve | 20-30% reduction | Moderate | Branch lines, low-flow fixtures |

| Gate Valve (Open) | Near 0% | Very Low | Municipal water mains |

Stainless steel or chrome-plated brass ball: which to choose for aggressive water?

Once you’ve settled on a full-port ball valve, the final piece of the puzzle is material selection. Not all ball valves are created equal, and the metal used for the ball and stem is critical for longevity, especially with the variable water chemistry found across Quebec. The two most common and reliable options for residential use are chrome-plated brass and stainless steel. A standard, uncoated brass ball is susceptible to dezincification and corrosion over time, particularly in “aggressive” water that might be softer or have a lower pH. This corrosion can roughen the ball’s surface, compromising the seal and making it harder to turn.

For most residential applications in the Montreal area, a chrome-plated brass ball offers an excellent balance of durability and cost-effectiveness. The hard, smooth chrome plating provides a robust protective layer against corrosion and mineral buildup, ensuring the valve operates smoothly for years. However, if you are on a well system or in an area known for particularly aggressive water, upgrading to a valve with a solid stainless steel ball and stem is a wise investment. Stainless steel offers superior corrosion resistance across a wider range of water conditions, making it the premium choice for ultimate peace of mind. While the initial cost is higher, it ensures the valve’s internal components remain pristine, guaranteeing a perfect seal when you need it most. As the experts at Gemini Valve note, longevity is the key:

Ball valves have a higher initial cost, but they are the better choice for longevity since they are more durable and highly effective at forming tight seals

– Gemini Valve Technical Guide, Gate Valves vs. Ball Valves: How to Choose the Right One

In very specific industrial or high-purity contexts, even more advanced materials like ceramic are used, but for a home, choosing between quality chrome-plated brass and stainless steel is the key decision for ensuring decades of reliable service.

Valve with drain (Stop & Waste): essential for outdoor faucets

In a climate like Quebec’s, any plumbing that runs outside is at risk of freezing and bursting. This is why properly winterizing your outdoor hose bibbs (faucets) is not just a suggestion, it’s an absolute necessity. The key to doing this effectively is a specific type of valve installed inside your home: the “Stop and Waste” valve. This valve, which should be a ball valve for all the reasons we’ve discussed, has a small secondary cap on its side. This isn’t just a random feature; it’s a drain port, and it’s crucial for protecting your pipes.

The process is simple but must be done in the correct order. Before the first deep freeze, you close the indoor Stop and Waste valve, cutting off the water supply to the outdoor faucet. Then, you go outside and open the hose bibb to let any trapped water out. The final, critical step is to return to the indoor valve and unscrew the little drain cap (the “waste” port), holding a small bucket underneath. This allows all the water remaining in the pipe *between* the indoor valve and the outdoor faucet to drain out completely. Without this step, that trapped water would freeze, expand, and split the pipe, causing a flood inside your walls come springtime. A Stop and Waste valve is the only correct way to isolate an outdoor line for the winter.

Your Action Plan: Quebec Winter Valve Winterization Checklist

- By Thanksgiving Weekend: Close indoor stop & waste valve completely

- Step 2: Open all outdoor faucets to release pressure

- Step 3: Open drain cap on indoor valve to evacuate remaining water

- Step 4: Leave outdoor tap slightly open through winter

- Spring restart: Close outdoor tap before reopening indoor valve

Water hammer on closure: how to close a ball valve without breaking the piping?

The greatest strength of a ball valve—its ability to shut off the flow of water instantly—can also be its one potential hazard if misused. Because ball valves require only a 90-degree quarter turn to go from fully open to fully closed, slamming the lever shut on a high-flow line can create a dangerous phenomenon known as water hammer. Water moving at high speed through pipes has a lot of momentum. When you stop that flow instantly, it creates a hydraulic shockwave that travels back through the plumbing system. This shockwave creates a loud “hammering” or banging sound and, under enough pressure, can weaken fittings, damage appliances, and even cause pipes to burst.

The solution is simple: awareness and proper technique. You should never slam a ball valve shut. Instead, turn the lever slowly and smoothly over 2 to 3 seconds. This gradual closure allows the water’s momentum to dissipate safely, preventing the creation of a shockwave. It’s a simple habit that completely mitigates the risk.

Under high enough pressure, a water hammer can cause a pipe to weaken and break. For that reason, users are advised to turn the ball valve lever slowly

– The Home Depot, Ball Valves vs Gate Valves Guide

For systems with particularly high pressure or fast-closing solenoid valves (like in washing machines), a dedicated water hammer arrestor can be installed. This is a small, sealed air chamber that acts as a shock absorber, cushioning any pressure spikes in the system. But for the main manual shutoff, the most effective tool is a slow, steady hand.

Where is the main water inlet hiding in a 1950s house?

In an emergency, the first step is always to shut off the main water supply. But in many older Quebec homes, particularly those built in the 1950s and 60s, finding this valve can be a frantic treasure hunt. Unlike modern builds where the valve is usually in a clearly marked utility room, older construction practices placed them wherever was most convenient at the time. Knowing the likely hiding spots *before* you need it is critical.

Your search should start in the basement. The water main enters your home from the street, so begin by locating the front foundation wall (the one facing the road). Follow this wall to a corner. The main pipe, typically a 3/4″ or 1″ copper or galvanized steel pipe, will emerge from the concrete foundation or floor. The main shutoff valve should be located on this pipe, usually within three feet of where it enters the house. In many classic Quebec bungalows, a common location is inside the “chambre froide” (cold room), a concrete-walled room often found under the front steps. Also, check any small utility closets or finished areas along that front wall. If a water meter is present, the valve will almost always be located right beside it. Take five minutes today to locate, tag, and test your valve. Those five minutes could save you thousands in water damage later.

When it comes to plumbing, having the proper valve in place will help ‘delay’ problems down the road. I use the term ‘delay’ instead of ‘prevent’, simply because when it comes to plumbing, problems will ALWAYS arise, it’s just a matter of how soon.

– Royal Plumbing

Here are the most common locations to check in a typical mid-century Quebec home:

- Check the front basement wall, directly inland from the street connection.

- Look inside the ‘chambre froide’ (cold room) under the front entrance steps.

- Search near the water meter if present (usually in the front corner of the basement).

- Inspect utility closets adjacent to exterior walls.

- Follow the largest pipe coming from the foundation wall—the valve is typically close by.

How to shut off water to a single faucet without turning off the whole house?

Replacing a kitchen faucet or fixing a leaky toilet shouldn’t require a full-house water shutdown. Modern plumbing practice dictates that every fixture—sinks, toilets, dishwashers—should have its own local shutoff valves, commonly called “angle stops” or “supply stops”. These are small, individual valves (one for hot, one for cold) located right under the fixture. Like their larger main-line counterparts, these stops have also evolved. The old, multi-turn stops suffer from the same problems as gate valves: they seize, they leak from the stem, and they often fail to close completely after years of inactivity.

The modern solution is the quarter-turn ball valve angle stop. They offer the same simple, reliable 90-degree turn for a positive shutoff. If you’re doing any renovation or even just replacing a faucet, upgrading these old multi-turn stops to quarter-turn ball valves is one of the smartest, most cost-effective improvements you can make. It transforms a future repair from a major plumbing job into a simple, localized task. For DIYers in Quebec, various connection types are available that don’t require soldering, making this an accessible and high-value upgrade.

For any homeowner planning a retrofit, understanding the different connection options is key. This table provides a quick comparison for common choices in Quebec.

| Connection Type | Installation Difficulty | Cost (CAD) | Best For |

|---|---|---|---|

| Push-to-Connect (SharkBite) | Easy/DIY | $25-40 | Copper/PEX retrofits |

| Compression Fitting | Moderate | $15-25 | Copper pipes only |

| Soldered | Professional | $10-20 + labor | Permanent installations |

Key Takeaways

- The primary reason to upgrade is reliability; a ball valve is designed to work after years of inactivity, whereas a gate valve is designed to fail.

- A “full port” ball valve is non-negotiable for a main shutoff to avoid permanently reducing your home’s water pressure.

- For Quebec’s water conditions, a chrome-plated brass or stainless steel ball offers the necessary protection against corrosion and seizing.

Why Does an Emergency Plumber Cost 3x More Than Scheduled Maintenance?

The sticker shock of an emergency plumbing bill often leaves homeowners reeling. The reason for the high cost is a combination of factors: immediate dispatch (pulling a plumber off another job), after-hours or weekend labor rates, and the urgency premium. Data shows that emergency plumbing services typically charge 3x higher rates or more compared to a scheduled appointment. A $200 scheduled repair can easily become a $600+ emergency call. But the most significant part of this equation is that the vast majority of these “emergencies”—burst pipes, uncontrollable leaks—are not sudden, random events. They are the direct result of a component failure that was predictable and preventable.

This is where the choice of a main water valve comes full circle. Relying on an old gate valve that you know is stiff or hasn’t been tested in years is not maintenance; it’s a bet against the odds. When that bet fails, you pay the emergency premium. Proactively replacing that old valve with a new, high-quality ball valve for a few hundred dollars on a scheduled visit is the ultimate form of preventive maintenance. It’s not just a repair; it’s buying an insurance policy against that future 3 AM, $600 disaster. A reputable plumber’s goal is to install parts that prevent future calls, not guarantee them.

A reputable plumber will always supply you with a better valve, and will also be able to install the best valve for you upon request

– Royal Plumbing

Investing in quality components upfront is the single most effective way to control long-term plumbing costs. The cost of a single emergency call often exceeds the cost of proactively replacing several key valves in your home. It’s about shifting from a reactive, expensive mindset to a proactive, cost-effective one.

Don’t wait for a 3 AM disaster. The most cost-effective plumbing decision you can make is to proactively upgrade your main water shutoff. Assess your current setup today and schedule a replacement to secure your home’s plumbing integrity for decades to come.