Your old, single-speed circulator pump is likely the secret energy hog and noise-maker in your heating system, silently inflating your Hydro-Québec bill.

- An ECM pump actively cuts its own electricity use by up to 85% by intelligently adapting its speed to your home’s real-time heating needs.

- This smart adaptation eliminates system pressure issues, putting an end to the annoying whistling and gurgling noises from radiators and baseboards.

Recommendation: Upgrade to an ECM pump to not only lower your electricity costs but to transform your entire hydronic system into a smarter, quieter, and more reliable asset for harsh Quebec winters.

If you’re a Quebec homeowner with a hydronic heating system, you’re familiar with the comforting warmth of radiators or baseboard heaters during a frigid January night. You’re also likely familiar with two unwelcome companions: a stubbornly high Hydro-Québec bill and the intermittent, frustrating symphony of hisses, whistles, and gurgles coming from your pipes. Many homeowners blame the boiler or the thermostats, investing in expensive upgrades that don’t solve the core issue. They follow the common advice of bleeding radiators or insulating pipes, which are helpful but often just treat the symptoms.

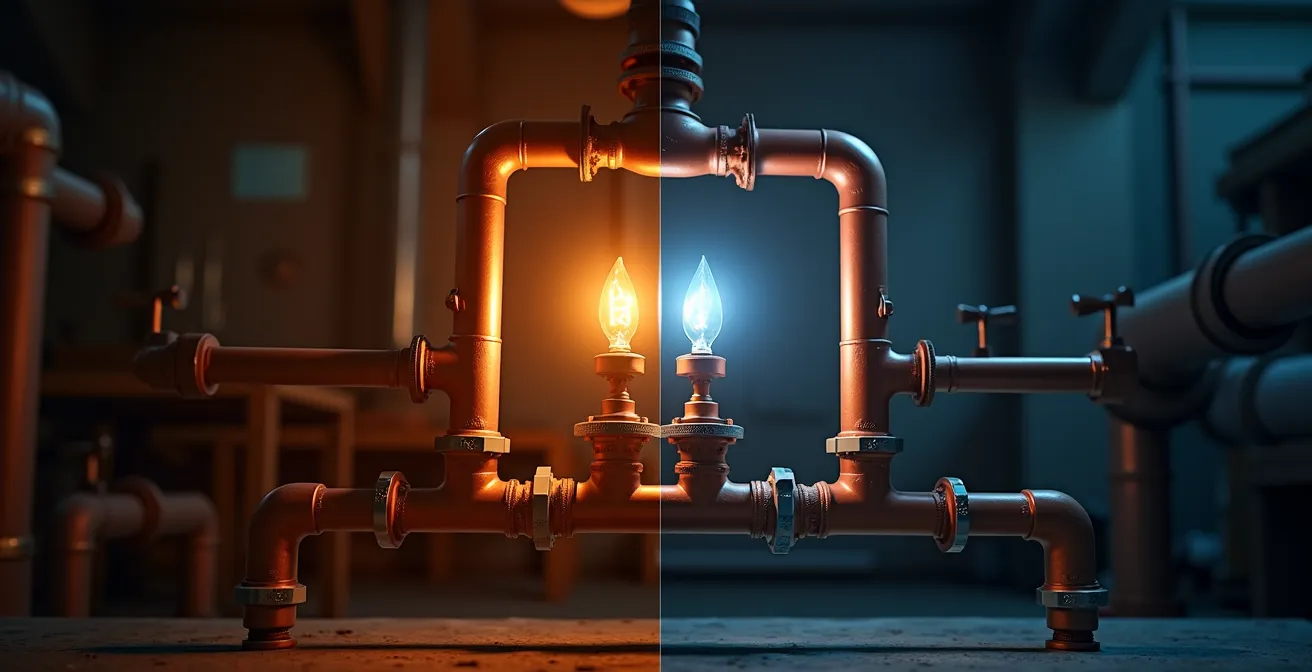

These conventional fixes overlook the system’s heart: the circulator pump. An old, standard pump is a brute-force machine, running at one speed whether your house needs a little or a lot of heat. This is like driving your car everywhere with the gas pedal floored, using only the brake to slow down—wildly inefficient and stressful on the entire system. But what if the solution wasn’t just to replace a part, but to install an intelligent ‘brain’ for your heating system?

Upgrading to a modern Electronically Commutated Motor (ECM) circulator pump is that transformative step. This isn’t merely a component swap; it’s an evolution from a dumb motor to a smart, responsive device. An ECM pump constantly monitors your heating system’s pressure and flow, dynamically adapting its speed and power consumption in real-time. This article will deconstruct exactly how this technology goes beyond simple energy savings to deliver a quieter, more comfortable, and more resilient heating experience tailored for the unique demands of a Quebec home, including how it can maximize your rewards from programs like Hilo.

We will explore the key operational modes, calculate the real-world return on investment, and explain how these pumps solve common problems and integrate with modern smart home technology. This guide provides the technical understanding you need to make a confident, energy-wise decision.

Summary: A Homeowner’s Guide to ECM Pump Technology and Savings

- Pression constante vs proportionnelle : quel mode choisir pour des vannes de zone ?

- Pompe ECM vs standard : le retour sur investissement se fait-il en 2 ou 5 ans ?

- Sifflement dans les radiateurs : comment la vitesse variable élimine-t-elle les surplus de pression ?

- Pompe universelle : peut-on remplacer n’importe quelle vieille pompe rouge par une ECM ?

- Fonction dégommage automatique : pourquoi votre nouvelle pompe ne saisira pas cet été ?

- Sonde extérieure : comment la courbe de chauffe optimise-t-elle la température de l’eau de la chaudière ?

- Boue noire (magnétite) : l’ennemi invisible qui tue les pompes ECM à aimant permanent

- How to Connect Your Hilo Smart Thermostat for Maximum Cash Back?

Constant Pressure vs. Proportional Pressure: Which Mode to Choose for Zone Valves?

One of the most significant upgrades an ECM pump offers is not just its efficiency, but its intelligence, manifested through its multiple operating modes. Unlike a standard pump that is only ‘on’ or ‘off’, a modern ECM circulator offers a sophisticated menu of choices. In fact, it’s common to find at least 5 different operating modes available in modern ECM circulators, but the two most critical for residential systems are Constant Pressure and Proportional Pressure. Choosing the right one is essential for maximizing both comfort and savings, especially in typical Quebec homes with multiple heating zones.

Think of your heating system. Do you have multiple thermostats controlling different areas (e.g., upstairs and downstairs)? If so, you likely have zone valves. When a zone doesn’t need heat, its valve closes. In a system with a standard, single-speed pump, this is a problem. The pump continues to push the same amount of water into a now-restricted system, causing pressure to build. This leads to noisy, whistling valves and unnecessary strain on the pump motor.

This is where Proportional Pressure mode becomes the clear winner for systems with zone valves. In this mode, the pump senses the pressure increase as valves close and automatically reduces its speed and output. This dynamic adaptation ensures that pressure remains stable, eliminating noise and saving energy. As detailed in an analysis of Canadian heating systems, this mode is ideal for setups with zone valves as it prevents valve whistling and premature failure during harsh Quebec winters. Conversely, Constant Pressure mode is best suited for systems with ‘home run’ piping (where each radiator has its own dedicated supply and return line) or systems with pressure-bypass valves, configurations more common in some newer Montreal construction projects.

ECM vs. Standard Pump: Is the Payback Period 2 Years or 5 Years?

For any energy-efficiency upgrade, the primary question for a homeowner is straightforward: “When will it pay for itself?” With ECM circulator pumps, the return on investment (ROI) is not a matter of ‘if’, but ‘how fast’. The payback period is surprisingly short, driven by the drastic reduction in electricity consumption. A standard “old red” pump can consume between 85 and 95 watts continuously. In contrast, an ECM pump’s consumption can drop to as low as 7 watts when the heating demand is low.

To put this in perspective, let’s analyze the real-world operating costs. The table below, based on data from a Northern Canadian climate similar to Quebec’s, illustrates the dramatic difference. It assumes an electricity rate of $0.10/kWh and continuous operation during the heating season.

This data, highlighted in an analysis of ECM pump operating costs, provides a clear financial picture.

| Pump Type | Power Consumption | Annual Cost | Annual Savings |

|---|---|---|---|

| Standard Pump | 92W | $258 | – |

| ECM Pump (Low Setting) | 7W | $20 | $238 |

| ECM Pump (High Setting) | 43W | $126 | $132 |

As the table shows, the annual savings can range from $132 to $238. Assuming the installed cost of an ECM pump upgrade is between $500 and $700, the simple payback period is typically between 2 and 4 years. This calculation doesn’t even factor in potential rebates from entities like Hydro-Québec or the secondary benefits of reduced wear and tear on other system components. This rapid ROI makes the ECM pump one of the most financially sound energy retrofits a Quebec homeowner can make.

The visual contrast in energy use is stark. It’s not an incremental improvement; it’s a fundamental shift in efficiency that directly translates into a lower electricity bill, making the investment profitable in just a few heating seasons.

Radiator Whistling: How Does Variable Speed Eliminate Excess Pressure?

That persistent whistling, hissing, or gurgling sound from your radiators isn’t just an annoyance; it’s the sound of your heating system under stress. It’s a clear symptom of ‘over-pumping’—a condition where your circulator pump is forcing more water through the pipes than they can handle. This commonly happens in zoned systems when only one or two zones are calling for heat, forcing the full output of the pump through a small fraction of the system’s piping.

An HVAC expert from the Canadian Plumbing & HVAC Magazine offers a perfect analogy to explain the difference between old and new technology in this scenario:

An old pump is like a garden hose with your thumb over the end when valves close—pressure and noise build up. An ECM pump is like easing off the tap—it senses the restriction and slows down automatically.

– HVAC Expert, Canadian Plumbing & HVAC Magazine

This “easing off the tap” is the core function of the pump’s variable-speed technology. Instead of fighting against the closed valves, the ECM pump’s internal logic detects the rise in pressure and instantly reduces its motor speed. By lowering the flow rate to match what the system can actually accept, it eliminates the turbulence and velocity that cause the noise. The result is a system that runs silently, regardless of how many zones are active. It brings a new level of auditory comfort to your home, especially in bedrooms or living areas where heating noises can be particularly disruptive.

This intelligent pressure management not only solves the noise problem but also protects your system’s components. The constant high pressure from an old pump can lead to premature failure of zone valves, seals, and gaskets. By maintaining a stable, appropriate pressure, the ECM pump extends the life of your entire hydronic system.

Action Plan: Eliminate Radiator Whistling with Your ECM Pump

- Identify the Trigger: Confirm that whistling occurs primarily when only one or two heating zones are active. This is a classic sign of over-pumping.

- Select the Right Mode: Switch your ECM pump to the “Proportional Pressure” or an equivalent “AUTOADAPT” mode. This setting is specifically designed for systems with thermostatic or zone valves.

- Adjust the Differential Pressure: Start with a medium setting for the pressure differential. The goal is to provide enough pressure to heat the furthest radiator without creating excess velocity when zones close.

- Monitor Performance: Listen to the system as different zones turn on and off. The ECM pump should automatically and quietly adjust its speed, eliminating the whistling.

- Fine-Tune for Your Home: Based on your specific layout, whether a Montreal duplex or a suburban bungalow, you may need to slightly increase or decrease the pressure setting to find the perfect balance of silent operation and effective heating.

Universal Pump: Can You Replace Any Old Red Pump with an ECM?

For decades, the hydronic heating landscape was dominated by a few models of standard, iron-bodied pumps, often red in color. This has led many Quebec homeowners to wonder if upgrading to a modern ECM pump is a complex, custom-fitting job. The answer, fortunately, is no. Modern ECM pumps are engineered with the specific goal of being true universal replacements.

Manufacturers have designed their flagship ECM models to have the exact same “flange-to-flange” dimensions as the legacy pumps they are meant to replace. This means that for the vast majority of installations, an ECM pump can be swapped in directly without any need to cut or modify existing pipework. This dramatically simplifies the installation process, reducing labor time and cost for the homeowner. It transforms the upgrade from a major plumbing project into a straightforward component replacement.

Furthermore, the efficiency gains are not just marginal. For instance, a leading manufacturer specifies that their popular ECM model consumes 85% less electricity compared to the traditional pump it often replaces, which is one of the most common models found in older Quebec homes. This level of efficiency, combined with the ease of a direct swap, makes the upgrade decision even more compelling. The universality extends beyond physical dimensions; a single programmable ECM model can be configured on-site to replicate the performance curves of dozens of different older, fixed-speed pumps, simplifying inventory for contractors and ensuring the homeowner gets the right performance for their specific system.

Automatic Purge/Self-Cleaning Function: Why Your New Pump Won’t Seize Up in Summer

A classic failure point for old heating circulators occurs not during the harsh winter, but after the long, dormant summer. During the months of inactivity, mineral deposits and microscopic debris in the system’s water can settle within the pump’s tight tolerances. This buildup can cause the pump’s rotor to seize, and when the thermostat calls for heat for the first time in October, the pump motor hums but fails to turn, resulting in a no-heat situation and a call for emergency service.

Modern ECM pumps have been engineered with an ingenious solution to this age-old problem: an automatic self-cleaning or “de-blocking” function. This feature acts as a built-in preventative maintenance routine. The pump’s internal controller is programmed to detect long periods of inactivity. If the pump hasn’t run for a set period, it will briefly activate itself to spin the rotor.

This short, periodic cycle is enough to break free any potential sediment or mineral scale before it can solidify and cause a seizure. For example, some models incorporate a feature where, for every 24 hours of downtime, an automatic anti-seizure function activates to turn the impeller. This “wake-up” function ensures that when the heating season begins, the pump is free and ready to operate reliably. For a Quebec homeowner, this means peace of mind, knowing that your heating system’s heart has been keeping itself in shape all summer, ready to perform flawlessly when the first cold snap arrives.

Outdoor Sensor: How Does the Heating Curve Optimize the Boiler’s Water Temperature?

An ECM pump is a powerful tool for efficiency, but its intelligence is truly unlocked when it works in concert with other smart devices, most notably an outdoor reset control (or outdoor sensor). This synergy creates a highly responsive and efficient system that anticipates the heating needs of your home rather than just reacting to them. An outdoor sensor is a small temperature probe installed on an exterior, north-facing wall of your house.

Its job is simple: it constantly measures the outside air temperature and reports it to your boiler’s controller. The controller then uses this information to adjust the temperature of the water it sends to your radiators based on a pre-programmed ‘heating curve’. The logic is intuitive: the colder it is outside, the hotter the water needs to be to keep your house comfortable. When it’s a mild 5°C, the boiler might only heat the water to 40°C. But when a Montreal winter storm drops the temperature to -20°C, it will heat the water to 65°C.

This is where the ECM pump’s role becomes crucial. As the boiler modulates the water temperature, the ECM pump, set to proportional pressure or an AUTOADAPT mode, adjusts the flow rate accordingly. This creates a beautifully synchronized system. A case study of a system in a climate with variable temperatures similar to Quebec’s found that the ECM pump smoothly handles temperature swings, preventing overheating and, most importantly, maximizing condensing boiler efficiency. A condensing boiler achieves its highest efficiency when the return water temperature is as low as possible. By preventing the system from overheating on milder days, the heating curve and ECM pump work together to ensure the return water is cool, allowing the boiler to operate in its most efficient condensing mode far more often, generating additional fuel savings beyond the electrical savings from the pump itself.

Black Sludge (Magnetite): The Invisible Killer of Permanent Magnet ECM Pumps

While ECM pumps are a pinnacle of efficiency and reliability, they have one critical vulnerability, especially in older homes common across Quebec: magnetite. Magnetite, also known as black sludge or iron oxide, is the result of natural corrosion occurring within systems containing iron or steel components, such as old cast-iron radiators or steel pipes. Over years, these microscopic, abrasive, and—most importantly—magnetic particles circulate throughout the system.

In a traditional pump, these particles often pass through without causing immediate failure. However, as expert Bob ‘hot rod’ Rohr, a trainer for Caleffi North America, explains, the design of an ECM pump changes the game: “ECM circulators have a permanent magnet rotor. So the small magnetic particles of magnetite can get stuck to that rotor and jam the pump.” This accumulation of magnetic sludge on the permanent magnet motor can act like glue, increasing friction, reducing efficiency, and ultimately leading to a seized motor and premature pump failure. It’s the equivalent of pouring sand into a high-performance engine.

Case Study: The Hidden Threat Revealed

In a system with cast iron components that had been operating for 10 years, the installation of a magnetic separator during a boiler upgrade revealed the extent of the problem. On the very first flush, the filter’s magnet was coated in a thick layer of black magnetite sludge. This case demonstrates that even in a seemingly “clean” system, this damaging material is present. For Quebec homes with cast iron radiators and steel pipes, a magnetic filter is not a luxury; it’s an essential ‘bodyguard’ for the ECM pump investment, continuously cleaning the system water and protecting the pump’s tight internal tolerances from destructive iron oxide buildup.

The solution is both simple and effective: installing a magnetic system filter. These devices are installed on the return pipework before the boiler and pump. They use a powerful magnet to capture and hold onto the circulating magnetite. With specifications showing that some models can achieve nearly 100% of magnetite removal from the system water, these filters effectively neutralize the primary threat to your ECM pump’s longevity. Protecting your new, high-efficiency pump with a magnetic filter is the single most important step to ensure a long and trouble-free service life.

Key Takeaways

- An ECM pump is an intelligent device that adapts its speed, not just a simple motor. This dynamic adaptation is what cuts energy use and eliminates noise.

- The return on investment is fast, typically 2-4 years, making it one of the most cost-effective energy upgrades for a Quebec home.

- To ensure longevity, especially in older homes with cast-iron radiators, pairing your ECM pump with a magnetic filter to capture “black sludge” (magnetite) is essential.

How to Maximize Your Hilo Cash Back with an ECM Pump

For savvy Quebec homeowners, participating in Hydro-Québec’s Hilo smart home service is a fantastic way to earn cash back by reducing electricity consumption during peak demand winter events. An ECM circulator pump is a powerful, often overlooked, tool to maximize these earnings. During a Hilo challenge, your smart thermostats will lower the temperature in your home. The goal is to use as little energy as possible during these critical hours.

A standard circulator pump, consuming 85-95W, becomes a significant energy draw during these events, eating into your potential rewards. An ECM pump, however, operates at a fraction of that power. When the thermostats lower the setpoint and zone valves close, the ECM pump’s power draw can drop to as low as 15-40W or even less. This minimal consumption during the challenge period directly translates to higher cash back rewards. According to program data, active Hilo program participants report an average savings of $155 during a single winter season, and minimizing every source of electrical draw is key to reaching or exceeding that number.

To fully leverage this synergy, you can optimize your heating strategy. By programming your thermostats to “pre-heat” your home in the hours leading up to a challenge, you can store thermal energy in the mass of your house. During this pre-heat phase, the ECM pump will circulate water efficiently and quietly. Then, when the challenge begins and the thermostats lower, the house stays comfortably warm for longer, while the ECM pump drops to its lowest power consumption mode. This combination of smart scheduling and low-wattage hardware ensures you meet the challenge goals without sacrificing comfort, turning your heating system into an active contributor to your Hilo rewards.

To fully capitalize on these efficiency gains and Hilo rewards, the logical next step is to have your system assessed by a qualified heating professional. They can recommend the right ECM model and confirm if a magnetic filter is needed, ensuring your upgrade delivers maximum savings and reliability for years to come.

Frequently Asked Questions About ECM Pump Upgrades

Can ECM pumps replace all traditional circulators?

Yes, ECM models like the Taco 0015e3 can replace ALL 3-speed hydronic circulators in their class, with universal flange-to-flange dimensions matching classic Armstrong and Taco models common in Quebec homes.

What about threaded vs flanged connections in older Quebec plumbing?

ECM pumps are available in both configurations. Adapter kits are available when needed to convert between connection types found in older Montreal and Quebec City homes.

How does one ECM pump replace multiple fixed-speed models?

A single ECM model can be programmed to replace dozens of different older fixed-speed pumps through its variable speed settings, simplifying inventory for contractors and selection for homeowners.