Residential & Industrial Plumbing

Plumbing systems form the invisible backbone of every building, yet the requirements for a single-family home differ dramatically from those of a manufacturing facility or a 30-story condominium tower. Whether you’re planning a bathroom renovation in your Montreal duplex or overseeing the installation of chemical waste lines in an industrial plant, understanding these distinctions is essential to ensure safety, compliance, and long-term reliability.

In Quebec, where harsh winters, strict building codes, and bilingual documentation requirements create unique challenges, both residential and industrial plumbing demand specialized knowledge. This comprehensive resource explores the fundamental differences between these two worlds, the regulatory framework governing them, and the practical considerations that ensure systems function flawlessly for decades. From drainage slope calculations to freeze protection strategies, we’ll demystify the core concepts that every property owner, facility manager, and construction professional should understand.

Understanding the Distinction: Residential vs. Industrial Plumbing Systems

The gap between residential and industrial plumbing extends far beyond scale. While a typical home serves 2-6 occupants with predictable water usage patterns, industrial facilities face wildly different demands: high-temperature effluents, chemical-resistant materials, continuous operation requirements, and regulatory oversight from multiple agencies.

Scale and Complexity Differences

Residential systems prioritize comfort and convenience, with fixture counts rarely exceeding 15-20 units. A typical Quebec home features copper or PEX supply lines, PVC drainage, and a single water heater. Industrial installations, by contrast, might include hundreds of fixtures, segregated waste streams, backup systems, and specialized equipment like grease interceptors, acid-neutralizing tanks, or compressed air networks that double as utility infrastructure.

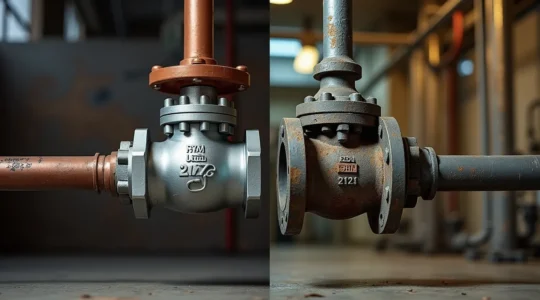

Material and Durability Requirements

The materials suitable for a residential bathroom vanish quickly in industrial settings. A food processing plant generating 85°C effluent requires cast iron or specialized high-temperature PVC, while chemical laboratories demand corrosion-resistant materials like polypropylene or stainless steel. Commercial buildings with high foot traffic need vandal-resistant fixtures—chrome-plated brass instead of plastic—and touchless technology to minimize maintenance in public restrooms serving hundreds daily.

Regulatory Compliance and Professional Standards in Quebec

Quebec’s construction landscape operates under the Code de construction du Québec, which references the National Plumbing Code of Canada while adding provincial modifications. Understanding these requirements isn’t optional—non-compliance can void insurance, delay project completion, and create significant financial liability.

Professional Accreditation Requirements

The Corporation des maîtres mécaniciens en tuyauterie du Québec (CMMTQ) strictly regulates who can perform plumbing work. Residential projects require licensed plumbers with specific endorsements, while industrial installations often demand additional certifications for pressure systems, refrigeration, or gas fitting. Before comparing quotes, verify that contractors hold current CMMTQ licenses and appropriate liability insurance—a critical step that protects your investment and ensures work meets legal standards.

Permit Navigation and Inspection Schedules

Most plumbing modifications beyond fixture replacement require municipal permits. The process varies significantly: replacing a water heater in a Laval bungalow involves a straightforward permit application, while converting a warehouse in Quebec City to multi-tenant commercial space triggers comprehensive plan reviews covering drainage separation, backflow prevention, and accessibility compliance. Smart planning schedules inspections at rough-in and final stages to avoid costly delays when walls are already closed.

Drainage and Ventilation: The Foundation of Every System

Proper drainage represents perhaps the most critical—and frequently misunderstood—aspect of plumbing design. Whether residential or industrial, gravity-based waste systems follow immutable physical principles that determine whether your installation functions silently for decades or creates persistent problems.

Calculating Optimal Drainage Slope

The ideal slope for drainage pipes balances two competing factors: sufficient velocity to carry solids without excessive turbulence that causes noise. For standard residential applications, the code specifies 1/4 inch drop per linear foot (approximately 2% grade) for most drain lines. Too steep, and water rushes ahead of solid waste; too shallow, and materials settle in the pipe, creating clogs. Industrial applications with grease-laden effluent might require modified slopes or specialized fittings to maintain flow.

Ventilation System Design

Every drain fixture requires proper venting to prevent siphoning of trap seals—the water barriers that block sewer gases. Residential systems typically use individual vents or wet venting strategies, while commercial buildings benefit from common vent stacks serving multiple floors. The key principle remains constant: atmospheric pressure must enter the drainage system to replace the volume of water flowing out, preventing that distinctive gurgling sound and eliminating persistent sewer odors that indicate inadequate venting.

Material Selection for Longevity

Drainage material choices carry decades-long implications. Cast iron delivers superior sound dampening—crucial in multi-family buildings where noise transmission affects property values—but costs more upfront. PVC offers affordability and corrosion resistance for most residential applications. Industrial settings might require specialized materials: polypropylene for chemical resistance, high-temperature PVC for commercial dishwashing operations, or stainless steel where hygiene standards are paramount.

Commercial and High-Rise Building Considerations

Vertical construction introduces challenges unknown in single-story residential work. Water pressure management, acoustic control, and maintenance accessibility become critical factors when systems span 20+ floors or serve hundreds of simultaneous users.

Pressure Management in Tall Buildings

Static water pressure increases approximately 0.43 PSI per vertical foot. A 25-story building creates over 100 PSI of pressure difference between ground and top floors—far exceeding safe operating limits for standard fixtures. Solutions include pressure-reducing valve zones every 8-10 floors, booster pump systems for upper levels, or segregated supply zones. Failure to address this creates catastrophic leak risks, shortened fixture life, and potential liability from water damage.

Acoustic Control Strategies

Nothing devalues a luxury condo faster than hearing toilets flush three floors above. Commercial-grade installations employ multiple sound-reduction strategies: cast iron drainage stacks, acoustic pipe wrap insulation, resilient mounting brackets that prevent vibration transmission, and careful routing that keeps plumbing chases away from bedrooms. These investments pay dividends in tenant satisfaction and reduced maintenance calls.

Maintenance Access and System Segmentation

Industrial and commercial systems must allow repairs without shutting down entire buildings. Strategic placement of isolation valves, cleanout access points, and segmented supply zones enables targeted maintenance. A well-designed high-rise can isolate a single floor or wing for repairs while maintaining service elsewhere—essential for hotels, hospitals, or multi-tenant office buildings where downtime directly impacts revenue.

Industrial Plumbing: Specialized Networks for Production Environments

Manufacturing, food processing, and chemical facilities require plumbing infrastructure that goes far beyond conventional water supply and drainage. These environments demand systems engineered for continuous operation, worker safety, and specialized waste handling.

Process-Specific Requirements

Industrial plumbing often includes networks rarely seen in residential work: compressed air systems powering pneumatic tools, process cooling water circuits, steam condensate return lines, or specialized drainage for high-temperature effluent exceeding 60°C. Each system requires distinct materials, pressure ratings, and safety considerations. A brewery’s clean-in-place (CIP) system operates at different pressures and temperatures than its potable water supply, demanding separate, clearly marked piping.

Waste Stream Segregation and Treatment

Environmental regulations in Quebec strictly govern industrial waste discharge. Food service operations require grease interceptors sized to flow rates and waste characteristics. Chemical facilities need neutralization tanks to adjust pH before municipal discharge. Automotive shops install oil-water separators. Proper sizing and maintenance of these systems isn’t optional—regulatory violations carry substantial fines and potential facility closure orders from provincial environmental authorities.

Reliability and Redundancy

When plumbing failure halts production, every minute costs money. Critical industrial systems incorporate redundant pumps, backup heating systems, and emergency shutdown protocols. A pharmaceutical clean room might feature dual supply pumps with automatic failover, backup power for critical systems, and continuous monitoring with alarm notification. This redundancy transforms plumbing from a passive utility into an active production asset.

Climate-Specific Challenges: Freeze Protection in Canadian Conditions

Quebec’s winter temperatures routinely plunge below -25°C, creating freeze risks unknown in milder climates. Both residential and industrial systems require robust protection strategies, particularly for exterior hose bibs, unheated spaces, and seasonal facilities.

Glycol Systems for Closed Loops

Hydronic heating loops, radiant floor systems, and process cooling circuits exposed to freezing conditions require antifreeze protection. Propylene glycol (safer for potable water proximity) or ethylene glycol (more efficient but toxic) gets mixed to concentrations matching the lowest expected temperature. A cottage heating system in the Laurentians might use 40% glycol protecting to -30°C, while a minimally heated warehouse uses 30% providing -15°C protection.

Circulation Pump Selection and Control

Stagnant water freezes; moving water resists freezing even at sub-zero temperatures. Critical systems employ circulation pumps with differential temperature controls that activate when ambient conditions approach freezing. Proper pump sizing ensures adequate flow velocity throughout the system—insufficient circulation leaves dead zones vulnerable to freeze damage despite antifreeze presence.

Testing and Maintenance Protocols

Glycol concentration and pH require annual testing. Degraded antifreeze loses freeze protection while becoming acidic enough to corrode copper and aluminum components. A simple refractometer test verifies concentration, while pH strips confirm fluid condition. Regular testing and timely fluid replacement transform freeze protection from a one-time installation into a ongoing maintenance commitment—far less expensive than repairing burst pipes in February.

System Optimization and Preventive Maintenance

Well-designed plumbing systems deliver decades of reliable service, but only with appropriate maintenance and strategic upgrades. Both residential and commercial installations benefit from proactive approaches that prevent failures rather than react to emergencies.

Hot Water Delivery Optimization

Waiting 60 seconds for hot water wastes thousands of liters annually while frustrating users. Recirculation loops with timer or demand-activated pumps deliver instant hot water while minimizing energy waste through proper insulation and intelligent controls. Even simpler solutions—under-sink point-of-use heaters or improved pipe insulation—significantly improve comfort and reduce waste in existing buildings.

Leak Detection and Prevention

Hidden leaks in walls or beneath concrete slabs cause extensive damage before detection. Modern systems incorporate leak detection technology: moisture sensors at vulnerable locations, flow monitoring that identifies unusual consumption patterns, or acoustic detection systems that identify leaks through sound signature analysis. In commercial buildings where a single leak can cause millions in damage, these technologies represent insurance rather than expense.

Whether you’re planning a residential renovation, managing a commercial property, or overseeing industrial facility operations, understanding the distinct requirements of residential and industrial plumbing systems empowers better decisions. Quebec’s unique regulatory environment, harsh climate, and bilingual documentation requirements add layers of complexity, but mastering these fundamentals ensures projects proceed smoothly, meet legal requirements, and deliver reliable service for decades. The investment in proper design, quality materials, and professional installation always costs less than correcting mistakes after the fact.

How to Get Instant Hot Water at Your Tap Without Wasting Gallons?

Achieving instant hot water is less about the pump itself and more about a complete, optimized system that prevents energy waste and pipe damage. A recirculation system must be intelligently controlled (not run 24/7) to make a real impact on…

Read more

Why Do Residential Valves Fail Within Months in Industrial Applications?

Using residential-grade valves in an industrial facility isn’t a cost-saving measure; it’s a direct route to premature failure, regulatory non-compliance in Quebec, and exponential long-term costs. Component failure is often systemic, stemming from a mismatch in pressure ratings (Class), material…

Read more

Why Propylene Glycol is Non-Negotiable for Your Quebec Garage Heating Loop

Relying on water alone for your garage’s radiant heating in Quebec is not a calculated risk; it’s an eventual catastrophe. The switch to propylene glycol is a mandatory upgrade for system survival. Glycol provides “burst protection” even if it turns…

Read more

What Are the Plumbing Requirements for Food Processing Plants in Quebec?

In Quebec’s food industry, compliant plumbing isn’t a cost center—it’s a core driver of operational uptime, safety, and profitability. Chronic failures in standard materials like PVC are not accidents; they are predictable outcomes of mismatched specifications that lead to expensive,…

Read more

How to Design Bathroom Layouts to Minimize Piping Costs?

In summary: True plumbing savings in Quebec come from intelligent system design, not just shorter pipes. Mastering the Quebec Construction Code for fixture loads and wet venting is non-negotiable. Grouping wet zones (kitchen, bath) and stacking them vertically are the…

Read more

An Engineer’s Framework for Solving Water Pressure Issues in Montreal High-Rises

The key to solving chronic water pressure complaints in a multi-story building is to stop treating symptoms and implement a systemic, building-wide asset management plan. Most “fixes” address individual units, ignoring the interdependent nature of a high-rise’s vertical plumbing ecosystem….

Read more

What Are the Critical Plumbing Standards for Quebec Schools and Hospitals?

Mastering Quebec’s plumbing code is less about ticking compliance boxes and more about strategic asset management that ensures long-term operational resilience and cost control. High-durability fixtures and robust piping (like Type L copper) lower the total cost of ownership, despite…

Read more

Why Do Your Drains Gurgle When You Flush the Toilet?

That gurgling sound from your drains isn’t just a simple clog waiting for a plunger. It’s a critical symptom that your home’s entire plumbing network is a struggling hydraulic system, gasping for air due to pressure imbalances. This guide reveals…

Read more

What Are the Unique Quebec Plumbing Code Rules for Basement Apartments?

Converting a basement in Quebec is a smart investment, but misinterpreting the plumbing code often leads to budget overruns and failed inspections. Key regulations go beyond simple permits, involving mandatory backwater valves, strict venting rules, and the potential loss of…

Read more

Why Hiring a Non-RBQ Plumber Risks a $5,000 Fine in Quebec?

Hiring an unlicensed plumber in Quebec isn’t just a gamble on quality; it is a direct violation that can void your home insurance and trigger massive personal liability far exceeding the initial savings. Work by non-RBQ contractors is a common…

Read more