For most Quebec renovations, PEX is the superior choice due to its unmatched climate resilience and significant cost-effectiveness.

- It excels in freeze-thaw cycles, drastically reducing the risk of burst pipes during our harsh winters.

- It significantly cuts down on labour costs, often making a full repiping project 40-50% cheaper than with copper.

Recommendation: Prioritize PEX-A for maximum flexibility and durability, and always ensure your project is handled by a plumber with a valid RBQ license to avoid severe penalties.

Embarking on a plumbing renovation in Quebec isn’t just about updating fixtures; it’s a critical decision about the long-term resilience of your home. Faced with the choice between traditional copper, versatile PEX, and affordable CPVC, many renovators focus on the upfront material cost. This often leads to a familiar debate: the proven longevity of copper versus the lower price tag of modern plastics. While these points are valid, they miss the most crucial factors for a Quebec homeowner.

The real challenge lies in selecting a system that can withstand our specific environmental and regulatory pressures. The question shouldn’t be “which pipe is cheapest?” but rather, “which pipe best mitigates the risks of a -30°C cold snap, potential power outages, our specific water chemistry, and the strict building codes enforced by the Régie du bâtiment du Québec (RBQ)?” This is a decision about risk management as much as it is about materials.

This guide moves beyond generic comparisons to analyze each option through the lens of a Quebec homeowner. We will dissect how each material performs when faced with the risk of freezing, the impact on your budget considering labour, its resistance to corrosion over decades, and the non-negotiable legal requirement of professional installation. By understanding these key factors, you can make an informed, strategic choice that protects your investment for years to come.

To help you navigate this important decision, this article breaks down the essential considerations. The following summary outlines the key topics we will cover to determine the most suitable plumbing material for your Quebec home.

Summary: A Renovator’s Guide to Choosing Plumbing Pipes in Quebec

- Quel tuyau pardonne le mieux si le chauffage coupe en plein hiver ?

- PEX vs Cuivre : combien économisez-vous en main-d’œuvre sur une maison complète ?

- Eau chlorée : pourquoi le CPVC ou le PEX résistent mieux que le cuivre fin ?

- Tuyaux silencieux : quel matériau absorbe le mieux le bruit de l’eau qui coule ?

- Longévité des tuyaux : le PEX durera-t-il aussi longtemps que le cuivre de 1950 ?

- Cuivre vs PEX : la différence de prix vaut-elle la durée de vie de 50 ans ?

- PEX-A ou PEX-B : lequel résiste mieux au gel et à la mémoire de forme ?

- Why Hiring a Non-RBQ Plumber Risks a $5,000 Fine in Quebec?

Quel tuyau pardonne le mieux si le chauffage coupe en plein hiver ?

For any Quebec homeowner, the primary environmental risk is a deep freeze, especially during a power outage. When water inside a pipe freezes, it expands with immense force. In rigid pipes like copper or CPVC, this pressure has nowhere to go, leading to cracks or catastrophic bursts. This is where cross-linked polyethylene (PEX) demonstrates its most significant advantage: remarkable flexibility. Its molecular structure allows it to expand and contract without damage.

Unlike rigid alternatives, PEX tubing is designed for climate resilience. According to extensive testing in freezing conditions, its flexibility allows it to survive low temperatures far better than copper or CPVC. While no pipe is completely “freeze-proof,” PEX is exceptionally “freeze-tolerant.” It can stretch to accommodate the expansion of ice and return to its original shape once thawed. This single property can be the difference between a simple inconvenience and a devastating flood, making it a superior choice for mitigating winter-related risks in attics, crawl spaces, and exterior walls.

While PEX offers a crucial layer of protection, proactive winterization remains essential for any plumbing system in Quebec. Taking preventative steps can further secure your home against the dangers of frozen pipes, regardless of the material used. These measures help maintain a stable temperature around your plumbing and reduce the likelihood of water freezing in the first place.

Your Winter Pipe Protection Checklist

- Insulate all pipes located in unheated areas like attics, garages, and basements.

- Seal air leaks around pipes where they pass through walls or floors to block cold drafts.

- Keep cabinet doors under sinks open during extreme cold snaps to allow warm air to circulate.

- During severe cold, let faucets connected to vulnerable pipes drip slightly to keep water moving.

- Consider installing a water temperature alarm that alerts you if an area approaches freezing point.

This inherent tolerance to freezing makes PEX a far more forgiving material for the realities of a Quebec winter. It provides peace of mind that a sudden cold snap is less likely to result in costly water damage and repairs.

PEX vs Cuivre : combien économisez-vous en main-d’œuvre sur une maison complète ?

While material costs are a factor, the most significant financial difference between PEX and copper lies in the installation labour. Copper plumbing is a craft that requires meticulous work: cutting rigid pipes to precise lengths, cleaning and deburring ends, applying flux, and soldering dozens, if not hundreds, of joints. Each connection is a point of potential failure and adds significant time to the project. This process is both time-consuming and skill-intensive, which directly translates to higher labour costs.

PEX, on the other hand, revolutionizes the installation process. Its flexibility allows installers to run long, continuous lines from a manifold directly to a fixture, bending the tubing around obstructions. This drastically reduces the number of fittings required. In fact, installation studies show that PEX requires fewer joints, which results in a much faster installation. Fewer joints also mean fewer potential leak points, increasing the long-term reliability of the system.

This efficiency difference has a dramatic impact on the total project cost. For a typical home renovation, choosing PEX over copper can reduce the overall price by 40-50%, with the majority of those savings coming directly from reduced labour hours. The following table illustrates the typical cost difference for repiping a mid-sized home.

| Material | Total Cost Range | Material Cost | Labor Savings |

|---|---|---|---|

| Copper | $8,000-$10,000 | 3x more expensive | Baseline |

| PEX | $4,000-$6,000 | 1/3 of copper price | 58-68% less expensive |

For a renovator in Quebec, this cost differential is a major strategic advantage. The savings realized from a PEX installation can be reallocated to other parts of the renovation, such as higher-quality fixtures or improved insulation, further enhancing the home’s value and efficiency.

Eau chlorée : pourquoi le CPVC ou le PEX résistent mieux que le cuivre fin ?

Beyond the immediate risk of freezing, the long-term integrity of plumbing is threatened by a less visible force: water chemistry. Municipal water supplies, including those in Quebec, are treated with chlorine to ensure safety. While vital for public health, this chlorine can be corrosive to certain materials over time, particularly copper. This process, known as pitting corrosion, can create microscopic pinhole leaks in copper pipes, leading to slow, hidden water damage that can go undetected for years.

This is where plastic pipes like PEX and CPVC (Chlorinated Polyvinyl Chloride) hold a distinct chemical advantage. As stated by the SharkBite Technical Team, “PEX is immune to corrosion and mineral build-up, and it’s not affected by electrolysis, which can cause small pinhole leaks in copper piping.” This immunity means that PEX and CPVC do not react with the chlorine in the water, ensuring their interior surfaces remain smooth and free from degradation over their entire service life.

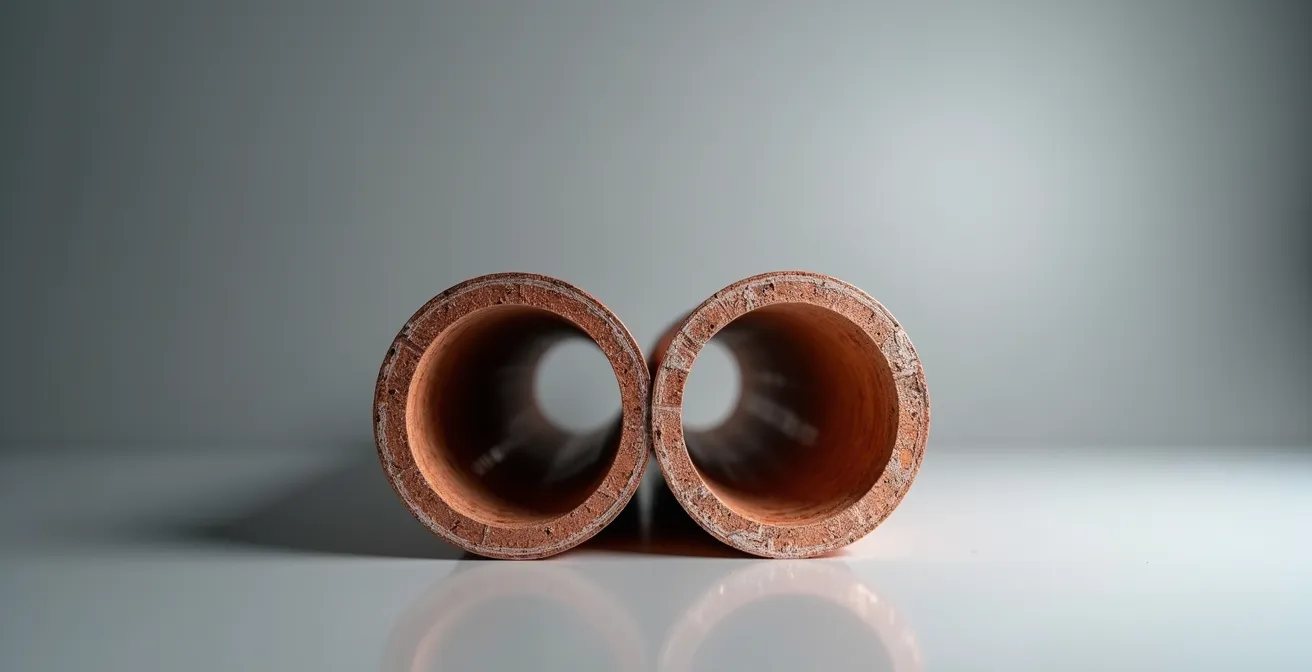

The image above clearly shows the internal damage that can occur in copper pipes over time due to chemical reactions with water. This internal scaling and corrosion not only weakens the pipe wall but can also affect water flow and quality. Furthermore, the manufacturing and life cycle of copper have a larger environmental footprint. According to a sustainability report, environmental studies indicate copper pipes waste about 32% more water over their life cycle compared to plastic pipes due to factors like leaks from corrosion.

PEX is immune to corrosion and mineral build-up, and it’s not affected by electrolysis, which can cause small pinhole leaks in copper piping

– SharkBite Technical Team, SharkBite Sustainability Report

For a Quebec renovator focused on long-term reliability, the inert nature of PEX and CPVC offers a significant advantage. It eliminates a key failure mode associated with copper, providing greater assurance that the plumbing system will remain intact and leak-free for decades.

Tuyaux silencieux : quel matériau absorbe le mieux le bruit de l’eau qui coule ?

A factor often overlooked during a renovation is the acoustic performance of the plumbing system. The sound of water rushing through pipes or the sudden thud of a “water hammer” when a valve closes can be a persistent annoyance in an otherwise quiet home. The material and design of the plumbing system play a direct role in how much noise is generated and transmitted through the building structure.

Rigid pipes like copper are excellent conductors of sound and vibration. The turbulence created at every 90-degree elbow and fitting, combined with the material’s rigidity, can lead to noisy operation. Water hammer, a pressure surge caused by the abrupt stop of water flow, is also more pronounced in rigid systems. These sounds can easily travel along the pipe and through walls and floors.

PEX offers a much quieter solution for two main reasons. First, its flexibility allows it to absorb vibrations and pressure surges rather than transmitting them. It acts as a natural dampener, effectively muffling the sound of water flow. Second, as mentioned previously, PEX installations use far fewer fittings. The long, sweeping bends possible with PEX create a smoother, less turbulent path for the water, which in itself results in quieter operation. The reduction in joints and turbulence is a key factor in creating a silent plumbing system.

While PEX is inherently quieter, certain installation practices can further enhance acoustic performance for any pipe type. Using insulated pipe clamps designed for sound dampening, installing pipe insulation with acoustic properties, and minimizing sharp turns in the layout can all contribute to a quieter home. However, the fundamental properties of PEX give it a clear starting advantage for homeowners who prioritize a peaceful living environment.

Longévité des tuyaux : le PEX durera-t-il aussi longtemps que le cuivre de 1950 ?

The most compelling argument for copper has always been its proven longevity. Homes from the mid-20th century still have functional copper plumbing, giving it a track record that modern materials can’t yet claim. However, comparing “old copper” to “new PEX” requires nuance. The copper pipes of the past were often thicker and installed in environments with different water chemistry. Today’s PEX is an advanced, engineered product designed for durability under modern conditions.

While copper can last 50-70 years, its lifespan is highly dependent on factors like water acidity and exposure to freezing, which can significantly shorten it. PEX and CPVC, while having a slightly shorter projected lifespan on paper, are not susceptible to the same type of corrosion that degrades copper over time. Modern PEX tubing is exceptionally durable, and its resilience has been proven in rigorous testing. For instance, testing demonstrates PEX maintains burst pressures well above specification even after being subjected to multiple freeze-thaw cycles, a critical consideration for Quebec.

The visual contrast between an aged copper pipe, often laden with mineral scale, and a pristine PEX pipe interior highlights another aspect of longevity: performance over time. PEX’s resistance to scale buildup ensures that water flow and pressure remain consistent throughout its service life. The following table provides a general comparison of expected lifespans and warranty periods.

| Material | Expected Lifespan | Warranty Period | Factors Affecting Longevity |

|---|---|---|---|

| Copper (Type L) | 50-70 years | Rarely warranted | Acidic water, freezing |

| PEX-A/PEX-B | 30-50 years | 25 years typical | UV exposure, high chlorine |

| CPVC | 50-75 years | 10-25 years | High temperatures, chemical exposure |

For a renovator, this means that while copper offers a potentially longer maximum lifespan, PEX provides a highly reliable 30-to-50-year service life free from the risks of corrosion and scaling, and backed by substantial manufacturer warranties. This represents a more than sufficient lifespan for most residential applications.

Cuivre vs PEX : la différence de prix vaut-elle la durée de vie de 50 ans ?

When weighing the upfront cost against the expected lifespan, homeowners must consider the total cost of ownership (TCO). While copper boasts a potential 50+ year lifespan, this benefit comes at a significant premium. As established, not only is the material itself more expensive, but the labour required for a copper installation can double the project’s total cost compared to PEX. For many, the question becomes whether this extra upfront investment is justified.

From a purely financial standpoint, PEX presents a compelling case. An analysis of overall costs reveals that a PEX installation is substantially more economical. In most scenarios, PEX tubing is less expensive than copper in terms of both material and labour, with overall project savings often reaching up to 60%. This TCO advantage makes PEX a financially pragmatic choice for the vast majority of residential renovations. The money saved can provide a better return when invested in other aspects of the home.

Furthermore, the long-term value proposition is not solely about maximum lifespan. It also includes maintenance and repair costs. A burst copper pipe due to freezing can lead to thousands of dollars in water damage repairs, a risk significantly mitigated by PEX. This “insurance” against common failures is a key part of PEX’s value. Many homeowners updating older Quebec homes are now actively choosing to replace existing copper with PEX, not just to save money, but also because its reliability and lower replacement costs are attractive features that appeal to future buyers.

Ultimately, while copper’s 50-year benchmark is impressive, the 30-50 year lifespan of a properly installed PEX system is more than adequate for most homeowners’ needs. When the huge upfront cost savings and superior resilience to common failure modes like freezing and corrosion are factored in, PEX often emerges as the choice with the best overall value and lowest total cost of ownership.

PEX-A ou PEX-B : lequel résiste mieux au gel et à la mémoire de forme ?

Once you’ve identified PEX as the likely best choice for your project, a further level of detail emerges: the distinction between PEX-A and PEX-B. These letters refer to the manufacturing process, which results in different physical properties. While both are excellent materials, PEX-A is generally considered the premium option, particularly for its superior flexibility and “thermal memory.”

PEX-A is manufactured using the Engel method, which results in the most uniform cross-linking and the most flexible product. Its key feature is its “shape memory”: if the pipe is kinked during installation, it can be gently heated with a heat gun, and it will return to its original form without any structural weakness. This significantly reduces waste and simplifies installation. PEX-B, made via the Silane method, is slightly more rigid and does not possess this same level of thermal memory. A kink in a PEX-B pipe typically means that section must be cut out and repaired with a coupling.

This superior flexibility also gives PEX-A better resistance to freezing. Its molecular structure allows for more expansion than PEX-B, providing a greater margin of safety against bursting. As an NREL Research Team noted, “PEX-a is a bit tougher than the rest.” The gold standard for a freeze-tolerant system is the combination of PEX-A tubing with expansion-style fittings, which create a strong, full-flow connection.

| Feature | PEX-A | PEX-B |

|---|---|---|

| Freeze Resistance | Superior – more flexible molecular structure | Good – but less expansion capacity |

| Shape Memory | Excellent – returns to original form with heat | Limited – less elastic recovery |

| Fitting System | Expansion fittings preferred | Crimp/clamp fittings |

| Flexibility | Can bend 3x diameter when heated | 5x diameter cold bend radius |

PEX-a is a bit tougher than the rest. The best tubing for freeze tolerance uses expansion fittings with PEX-A

– NREL Research Team, National Renewable Energy Laboratory freeze testing study

While PEX-B is a perfectly serviceable and reliable material that still offers all the core benefits over copper, the additional resilience and installation advantages of PEX-A make it the recommended choice for a renovator seeking the highest level of performance and long-term peace of mind in the demanding Quebec climate.

Key Takeaways

- PEX’s flexibility gives it superior freeze tolerance, a critical advantage in Quebec’s climate that drastically reduces the risk of burst pipes.

- The installation of PEX is significantly faster and requires fewer fittings than copper, leading to labour savings that can cut the total project cost by 40-50%.

- For maximum durability and resilience, PEX-A is the superior choice over PEX-B due to its better flexibility and thermal memory.

Why Hiring a Non-RBQ Plumber Risks a $5,000 Fine in Quebec?

After carefully selecting the best material for your home, the single most important decision is choosing who will install it. In Quebec, plumbing is a regulated trade for a reason: improper installation can lead to catastrophic leaks, health hazards, and major property damage. The Régie du bâtiment du Québec (RBQ) and the Corporation des maîtres mécaniciens en tuyauterie du Québec (CMMTQ) oversee the industry to protect the public. Hiring an unlicensed individual to perform plumbing work is not just risky—it’s illegal.

As the building owner, you are legally obligated to ensure any plumbing work is performed by a licensed contractor. The penalties for non-compliance are severe. While the title mentions a $5,000 fine, the reality can be much worse. According to the official RBQ penalty schedule, fines for individuals carrying out work without a license can start in the thousands and climb significantly higher for companies. Furthermore, your home insurance may refuse to cover damages resulting from work done by an unlicensed plumber, leaving you fully liable for all repair costs.

The RBQ states this clearly: “As the owner or manager of a building, you must make sure you give your plumbing work to be done only to licensed contractors.” A licensed plumber holds the necessary qualifications (a competency certificate), is bonded, and carries liability insurance. This is your protection against faulty workmanship. Verifying a contractor’s license is a simple but crucial step.

- Look for the RBQ and CMMTQ logos on their vehicle, website, and business card.

- Ask to see their physical RBQ license card before any work begins.

- Use the RBQ’s online public registry to confirm the license is valid, current, and covers the subclass for plumbing (15.5).

Choosing the right pipe is a technical decision. Choosing the right plumber is a critical legal and financial one. The savings offered by an unlicensed handyman are insignificant compared to the immense financial and safety risks you would be taking on.

To ensure your renovation’s success, compliance, and long-term durability, the final and most critical step is to engage a qualified, licensed plumbing professional. Always verify their RBQ credentials before committing to any work.