Contrary to the old adage, a fitting’s weight is not the ultimate sign of quality; its true durability is written in its metallurgical composition and its certification marks.

- The tell-tale pink stain on brass (dezincification) is a sign of imminent failure, especially in Quebec’s soft water conditions.

- Official certification shields (like cUPC and CSA) are the only reliable proof a fitting meets North American safety and lead-free standards.

- Mixing North American (NPT) and European (BSP) threads is a guaranteed recipe for a leak due to incompatible geometry.

Recommendation: For any installation in Quebec, make verifying the cUPC and CSA-C/US markings on every brass fitting a non-negotiable step before purchase.

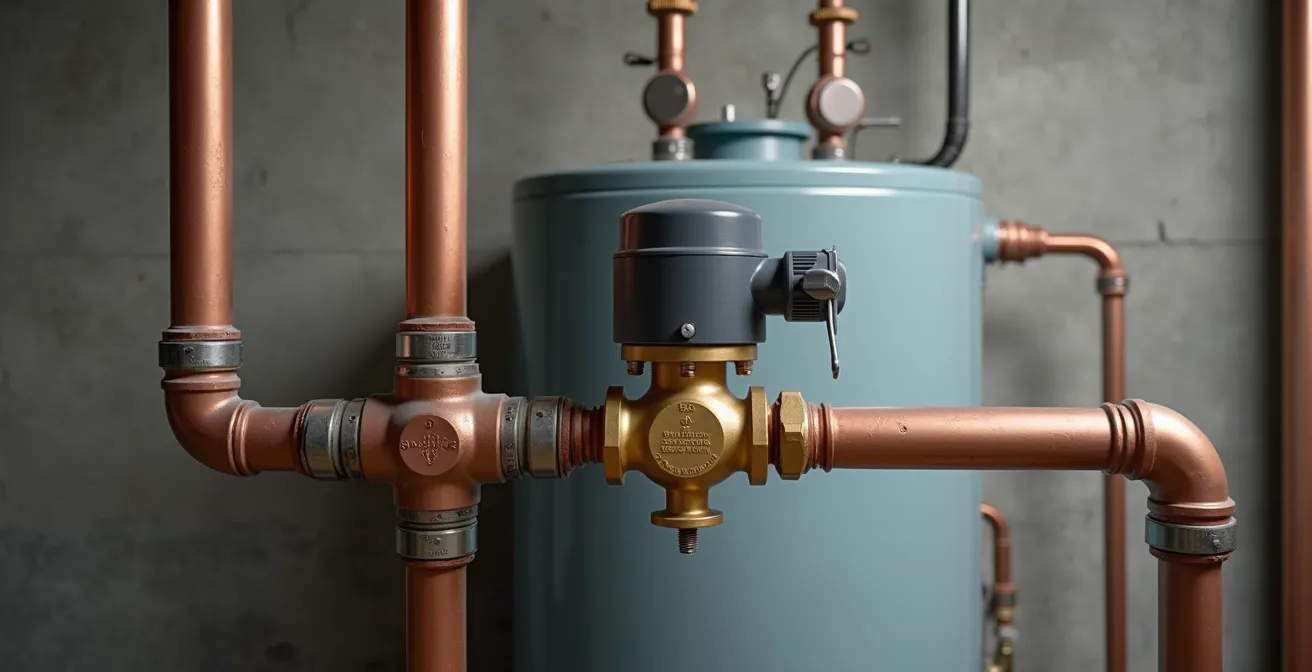

There’s no greater frustration for a professional than a callback for a leak on a job you thought was finished. You did everything by the book, yet a fitting has failed, causing water damage and eroding your client’s trust. The common wisdom is to judge brass fittings by their heft or their shiny finish, but this is a dangerously outdated approach. A heavy, polished piece of brass can still hide a ticking time bomb within its metallic structure, especially in the unique conditions found across Quebec, from the soft water of Montreal to the harsh freeze-thaw cycles of the regions.

The real culprits are often invisible to the naked eye: an improper zinc-to-copper ratio in the alloy, the absence of crucial lead-free certifications, or a microscopic mismatch in thread geometry. These are not minor details; they are fundamental flaws that determine whether a fitting will last for decades or crumble into a porous, pinkish mess in under two years. This is where a metallurgist’s perspective becomes essential. It’s about learning to read the language of the metal itself and understanding the critical importance of certifications designed for our North American plumbing ecosystem.

This guide moves beyond simplistic advice. We will dissect the science behind premature brass failure, show you how to identify the non-negotiable certification marks that guarantee compliance and safety, and reveal the subtle but critical differences in hardware that can make or break an installation. Consider this your field manual for identifying and rejecting substandard components before they ever make it into your toolbox, ensuring every connection you make is built to last.

To navigate these critical details, this article is structured to build your expertise step by step. Below is a summary of the key areas we will cover, from the chemical reactions that destroy brass from within to the practical differences between valve types that matter most in our climate.

Summary: A Metallurgist’s Guide to Brass Fitting Integrity

- Dezincification: Why Do Your Brass Fittings Turn Pink and Brittle?

- Lead-Free: How to Recognize the Official Marking on a Faucet?

- NPT vs. BSP: Why Does Screwing a European Fitting onto an American Pipe Guarantee a Leak?

- Compression Fittings: When Are They More Reliable Than a Poorly Made Solder Joint?

- Motorized Valves: Piston or Ball for Maximum Reliability in Heating?

- The Metal Contact Error That Perforates Your Copper Pipes in 5 Years

- Carbon Filter or Reverse Osmosis: Which to Choose to Drink Tap Water Without Fear?

- Why Are Quarter-Turn Ball Valves Superior to Old Gate Valves?

Dezincification: Why Do Your Brass Fittings Turn Pink and Brittle?

The most alarming sign of a cheap brass fitting is a phenomenon called dezincification. It’s the metallurgical cancer of bad plumbing. When you see a brass fitting developing a distinct pink or reddish hue, you’re not seeing surface tarnish; you’re witnessing the alloy disintegrate from the inside out. This process occurs when zinc is selectively leached from the brass alloy by corrosive water, leaving behind a porous, weakened copper structure that has lost all its mechanical strength. It becomes brittle and prone to cracking under the slightest pressure or temperature change.

This chemical reaction is significantly accelerated in alloys with a high zinc content. In fact, plumbing industry standards identify that dezincification risk skyrockets in brass alloys containing more than 15% zinc. Cheaper fittings often cut costs by using high-zinc brass, making them ticking time bombs. This is particularly relevant in Quebec, as a study from the Canadian Conservation Institute highlights that soft water conditions, common in many Quebec municipalities, can significantly speed up this corrosive process.

The visual evidence is undeniable. As shown in the comparison, healthy brass has a uniform yellow color and solid structure. In contrast, the dezincified section is porous and pink, a clear indicator that the fitting’s integrity is compromised. A fitting in this state is a failure waiting to happen, ready to cause a catastrophic leak. Spotting this pinkish plague is a critical skill for any professional who values their reputation.

Lead-Free: How to Recognize the Official Marking on a Faucet?

Beyond corrosion, the most critical factor for health and legal compliance is ensuring your fittings are “lead-free.” Since 2014 in Canada, all plumbing components that carry potable water must meet stringent low-lead requirements. For a plumber or builder in Quebec, installing a non-compliant fitting is not just a risk to your client’s health; it’s a breach of the National Plumbing Code. The term “lead-free” itself is legally defined as having a weighted average lead content of no more than 0.25% across the wetted surfaces of the component.

So, how do you verify compliance on the job site or when ordering online? You must learn to recognize the official certification marks. A simple “LF” stamp is not enough. For the Canadian market, the key logos to look for are from accredited bodies like the CSA Group or IAPMO. These organizations test and certify that products meet the required standards, including NSF/ANSI 372 for low-lead content.

The most common and trusted marks you should be looking for are the cUPC shield (Uniform Plumbing Code, certified for Canada) and the CSA logo, often with small “C” and “US” indicators to show it’s compliant for both Canada and the United States. The absence of these registered certification shields on a fitting or its packaging is a massive red flag. It often means the product has not been tested and is likely illegal to install in a potable water system in Quebec.

Your Checklist for Verifying Lead-Free Fittings

- Check for Certification: Look for the official CSA certification mark with ‘C’ and ‘US’ indicators, or the cUPC shield logo. These are non-negotiable.

- Verify Low-Lead Markings: Ensure “Low-Lead,” “LF,” or “NL” (No-Lead) is marked alongside the certification logo.

- Confirm NSF/ANSI 372: The packaging or spec sheet should confirm compliance with NSF/ANSI 372, which is the specific standard for lead-free material.

- Scrutinize Online Listings: Avoid sellers using generic photos or those who cannot provide certification numbers upon request.

- Prioritize Canadian Presence: When possible, buy from suppliers with a clear Canadian distribution presence to ensure accountability and easier warranty claims.

NPT vs. BSP: Why Does Screwing a European Fitting onto an American Pipe Guarantee a Leak?

One of the most frustrating and costly mistakes is a persistent, slow leak at a threaded connection that just won’t seal, no matter how much tape or sealant you apply. In many cases, the culprit isn’t a faulty product but a fundamental incompatibility between thread standards. North America and Europe use two completely different systems: NPT (National Pipe Thread) and BSP (British Standard Pipe). While they may look similar to the untrained eye, attempting to connect them is a guaranteed failure.

The incompatibility stems from three core differences in their geometry. First, the angle of the threads is different: NPT threads have a 60-degree angle, while BSP threads have a 55-degree angle. Second, their pitch (threads per inch) is different for most common sizes. Finally, NPT threads are always tapered to create a seal by friction, whereas BSP can be either tapered (BSPT) or parallel (BSPP). Because of these geometric variations, you might be able to get an NPT and BSP fitting to engage for two or three turns, giving a false sense of a proper connection before it binds up. This partial connection will never create a reliable, leak-proof seal.

This issue is increasingly common in Quebec as high-end European fixtures and appliances become more popular. A beautiful Italian faucet or a German heating component might come with BSP threads, which are completely incompatible with the standard NPT pipes and fittings sold in every Quebec hardware store.

| Feature | NPT (North American) | BSP (British/European) |

|---|---|---|

| Thread Angle | 60 degrees | 55 degrees |

| Thread Form | Tapered (1:16) | Parallel or Tapered |

| Thread Pitch | 11.5 threads/inch (1/2″) | 14 threads/inch (1/2″) |

| Common in Quebec | Standard in all hardware stores | High-end European fixtures only |

| False-Fit Risk | 2-3 turns before binding occurs | |

Compression Fittings: When Are They More Reliable Than a Poorly Made Solder Joint?

In the world of plumbing, soldering copper pipes is often seen as the gold standard for a permanent, robust connection. However, a perfect solder joint requires skill, cleanliness, and proper heat control. A poorly executed solder joint—one that’s overheated, under-heated, or contaminated—is a weak point that’s far more likely to fail than a properly installed compression fitting. This is where compression fittings find their place as a highly reliable, and often superior, alternative, especially for repairs or in situations where using a torch is impractical or dangerous.

Compression fittings create a mechanical seal by tightening a nut that compresses a ferrule (or “olive”) onto the pipe. This action deforms the ferrule, causing it to bite into the pipe and the fitting body, creating a strong, watertight connection without heat. For DIY repairs or for professionals working in tight spaces like under a sink, they are an excellent choice. As one plumbing expert notes, “Compression fittings provide a leak-proof seal with simple wrench turns, without the drama of soldering.”

However, their reliability is conditional. They must be installed correctly and used in the right applications. In Quebec, special consideration must be given to our climate. They should only be installed in heated spaces or locations fully protected from freezing, as the expansion and contraction from a freeze-thaw cycle can compromise the seal. Furthermore, it’s critical to ensure the copper tubing is cut squarely and properly deburred before installation, as any imperfection on the pipe surface can create a path for a leak. For natural gas lines, specific flare fittings are typically required by Quebec code, not standard compression fittings.

Motorized Valves: Piston or Ball for Maximum Reliability in Heating?

In modern hydronic heating systems, motorized zone valves are the brains of the operation, directing the flow of hot water to different areas of a home. When selecting these critical components, the internal mechanism—typically a piston, globe, or ball design—has a massive impact on long-term reliability. While older systems often used piston or globe-style zone valves, the clear winner for durability and trouble-free operation, especially in the context of Quebec’s water and climate, is the motorized ball valve.

The superiority of the ball valve design lies in its simplicity and functionality. It uses a perforated ball that rotates 90 degrees to open or close the flow path. This wiping action helps to clear away any mineral deposits or sediment that might otherwise cause a valve to seize. In contrast, piston and globe valves rely on a rubber seal being pressed down onto a seat, making them far more susceptible to sticking or failing to close completely due to scale buildup over time. Professional installation of quality components like ball valves is key, as one study on water system components shows that professional installation reduces related issues by up to 25%.

The reliability of a ball valve is especially crucial for any valve that may sit unused for long periods, like an emergency shut-off. A ball valve is far more likely to operate perfectly after years of inactivity. This is why full-port ball valves are now the standard recommendation for main water shut-offs. Their robust design ensures they will work when you need them most, a critical consideration for any plumbing system in a Quebec home.

The Metal Contact Error That Perforates Your Copper Pipes in 5 Years

One of the most insidious forms of corrosion in a plumbing system has nothing to do with water quality or a faulty fitting. It’s an electrochemical reaction called galvanic corrosion, and it occurs when two dissimilar metals are in direct contact in the presence of an electrolyte (water). This creates a natural battery, where one metal (the anode) corrodes at an accelerated rate to protect the other (the cathode). A classic and disastrous example is connecting copper pipe directly to galvanized steel pipe or using steel hangers to support copper tubing.

In the copper-steel pairing, the more reactive steel becomes the anode and sacrifices itself, leading to rust, scale, and eventual perforation of the galvanized pipe or fitting. When brass fittings are connected to stainless steel, the brass is typically the more active metal and will corrode. This process can silently destroy a plumbing system in as little as five years. The problem is especially prevalent in older homes, such as those found in many Montreal boroughs, during renovations where new copper plumbing is tied into an existing galvanized steel system without proper precautions.

The solution is to electrically isolate the metals from each other. This is achieved by using a special fitting called a dielectric union. This fitting has a plastic or rubber gasket that creates a physical barrier, breaking the electrical circuit and stopping the galvanic action. Simply using Teflon tape is not enough, as the metal threads can still make contact. The financial incentive is clear; industry analysis shows that using quality pipes and proper dielectric separation can lower repair costs by up to 70% by preventing these premature failures.

Carbon Filter or Reverse Osmosis: Which to Choose to Drink Tap Water Without Fear?

While Quebec’s municipal water is treated to high safety standards, many homeowners seek to further improve its taste, odour, and purity. The two most common point-of-use filtration technologies are activated carbon filters and reverse osmosis (RO) systems. Choosing between them depends entirely on your specific water goals and an understanding of our local water profile. A water treatment specialist from a Quebec water quality assessment program notes, “Quebec’s soft water is already low in minerals, and health benefits of removing potential contaminants far outweigh negligible mineral loss,” which helps frame the decision.

Activated carbon filters are excellent at adsorbing chlorine, pesticides, and volatile organic compounds (VOCs), which are the primary culprits behind bad taste and odours. They are relatively inexpensive, easy to install, and waste no water. For the vast majority of homes in Quebec with soft, municipally treated water, a quality carbon filter is the most sensible and cost-effective choice for great-tasting drinking water.

Reverse osmosis systems, on the other hand, offer a much higher level of filtration. They use a semipermeable membrane to remove up to 99% of all dissolved solids, including minerals (like calcium and magnesium), heavy metals (like lead), and salts. While this sounds superior, it comes with significant trade-offs. RO systems are more expensive, require more maintenance, and are notoriously inefficient, wasting 3 to 4 gallons of water for every gallon of purified water produced. Because they strip healthy minerals, they are generally considered overkill for Quebec’s already soft water and are better suited for regions with very hard water or specific contamination concerns.

| Feature | Carbon Filter | Reverse Osmosis |

|---|---|---|

| Initial Cost | $50-200 | $300-800 |

| Annual Maintenance | $40-80 | $100-200 |

| Chlorine Removal | Excellent | Excellent |

| Mineral Removal | Minimal | 95-99% |

| Water Waste | None | 3-4 gallons per 1 filtered |

| Best for Quebec | Most homes (taste/odor) | Hard water areas only |

Key Takeaways

- Dezincification, the “pink plague” of high-zinc brass, is a sign of imminent structural failure and is accelerated by Quebec’s soft water.

- CSA and cUPC certification marks are the only non-negotiable proof of a fitting’s compliance with Canadian lead-free and safety standards.

- North American (NPT) and European (BSP) threads are geometrically incompatible; mixing them will always result in a leak.

Why Are Quarter-Turn Ball Valves Superior to Old Gate Valves?

For decades, the multi-turn gate valve was the standard for main water shut-offs. However, experience has shown this design to be deeply flawed, especially in a climate like Quebec’s. A gate valve relies on a sliding “gate” that moves up and down to open or close the flow. This mechanism is highly susceptible to seizing from mineral deposits and corrosion, particularly if left untouched for years. It’s a common story: in an emergency, you run to the basement to shut off the main water supply, only to find the old gate valve is frozen solid and won’t budge.

This is where the modern quarter-turn ball valve proves its absolute superiority. As detailed in case studies of plumbing failures, its design is inherently more reliable. A ball valve uses a simple, robust mechanism where a quick 90-degree turn of the handle rotates a ball to immediately stop the flow. This quick, wiping action helps shear off any minor scale buildup, preventing the valve from seizing. Its reliability after long periods of inactivity is a critical safety feature.

Case Study: Gate Valve Failures in Quebec’s Winter

Numerous field reports from Quebec plumbers highlight that gate valves are a frequent point of failure. Their tendency to not close 100% after years of use makes it impossible to properly winterize outdoor taps, leading to burst pipes from frost damage. In contrast, quarter-turn ball valves provide a positive, complete shut-off every time, maintaining their reliability even after being untouched for an entire season. For this reason, replacing old gate valves with new ball valves during any renovation is now considered best practice.

Furthermore, ball valves provide a clear visual indication of their status—handle aligned with the pipe means open, perpendicular means closed—eliminating any guesswork. When selecting a ball valve for a main shut-off, choosing a full-port version is essential to ensure there is no reduction in water flow or pressure to the home. The evidence is overwhelming; for any new installation or renovation, the quarter-turn ball valve is the only professionally responsible choice for critical shut-offs.

Ultimately, safeguarding your work and reputation comes down to a commitment to quality that goes beyond the surface. By learning to identify the subtle signs of inferior alloys, verifying every certification mark, and respecting the precise engineering of components like valves and threads, you elevate your practice from simply connecting pipes to building truly resilient and safe plumbing systems. Adopt this metallurgist’s eye for detail on every job.